Services

- Home

- Project Details

Grease Trap Cleaning:

A grease trap is an indispensable plumbing device engineered to capture and collect fat, oil, and grease (FOG) from wastewater before it enters the municipal sewage system. Typically found in commercial kitchens, restaurants, and other food preparation facilities, these grease traps prevent FOG from obstructing pipes, causing troublesome blockages from food waste or solid waste and resulting in costly backups.

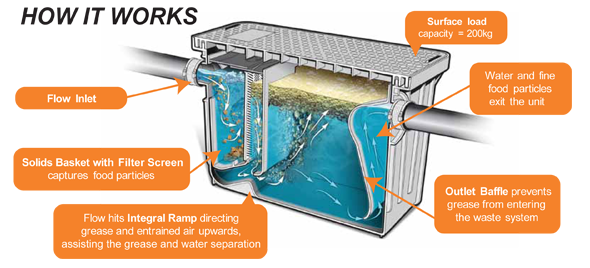

How Grease Traps Function:

The operation of a grease trap is ingenious. It allows wastewater to pass through a series of baffles strategically designed to decelerate the water’s flow and effectively trap the FOG. Due to its lower density than water, the FOG naturally rises to the surface, while the denser solids settle at the bottom within a dedicated sludge tank. The water continues its course in the middle layer, eventually exiting the trap via a dedicated pipe connecting to the municipal drainage system.

These traps comprise two core components: the grease trap itself, complete with baffles, including primary and secondary ones, and the essential sludge tank. The system’s efficacy hinges on the principles of density and weight, allowing for the efficient separation of grease, water, and solids. Over time, grease traps come in various sizes and designs, demanding regular cleaning and maintenance attention to ensure optimal performance on a regular basis.

Grease Trap Service Explained:

A grease trap service entails comprehensive cleaning and meticulous and proper maintenance, ensuring the peak performance of a grease trap. Regular servicing is vital to stave off blockages, prevent backups, and eliminate foul odors from accumulated grease waste, food solids, wastewater, food particles, and more. Professional grease trap cleaning services typically include removing accumulated FOG and debris, flushing the trap with clean water, and conducting thorough inspections for any signs of damage or wear and tear. The frequency of grease trap service varies based on factors such as the trap’s size, wastewater volume, and strict adherence to local regulations. In most instances, commercial kitchens and restaurants should schedule grease trap service and grease trap waste cleaning every three to six months.

The Benefits of Grease Trap Maintenance and Cleaning:

Enhanced Hygiene: Consistent Grease Trap Service is your shield against the accumulation of FOG (Fats, Oils, and Grease) and other waste, upholding a pristine kitchen and reducing the risk of food contamination.

Savings on Expenses: Routine Grease Trap Cleaning and Service prevent clogs and backups, sparing you from costly repairs and prolonging your grease trap’s lifespan, reducing the need for expensive replacements.

Regulatory Compliance: Numerous local authorities mandate regular Grease Trap Service, safeguarding you against fines and penalties.

Effective Odor Control: FOG can generate unpleasant odors from the grease trap. Regular service efficiently eradicates these odors, fostering a more pleasant work atmosphere.

Optimized Wastewater Treatment: A well-maintained grease trap is indispensable for impeccable wastewater treatment and pollution prevention. Regular service guarantees your trap functions optimally, averting wastewater complications downstream.

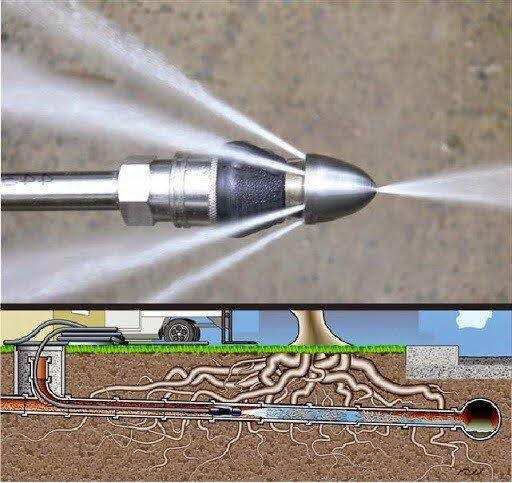

Hydro Jetting:

Hydro jetting employs high-pressure water jetting to clean and unblock drains effectively. Unlike traditional methods, hydrojetting uses water pressures from 500 to 40,000 PSI, making it ideal for removing tough blockages. This method is eco-friendly, avoiding harsh chemicals and minimizing waste.